Bill of Materials (BOMs) for Asset Management

BOMs for Asset Management

There is no denying that bills of materials make maintenance and supply chain organizations more efficient, intelligent, productive, and profitable. BOMs provide critical data to:

- Set min/max levels

- Reliability insights for which parts or components are “bad actors”

- Reduce MRO Spares on hand

Understanding Min/Max requirements with BOMs

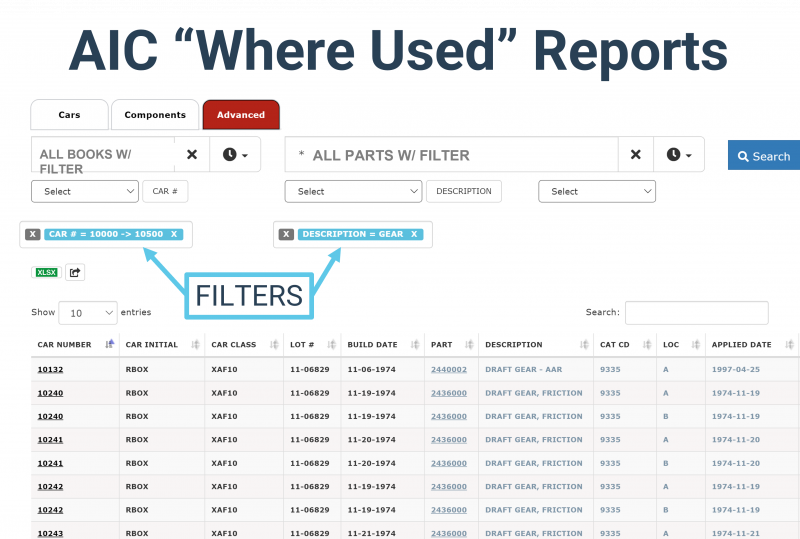

Often times, a part is used in many different assets and in multiple locations within each equipment. It is critical to understand where a part is used, to correctly stock MRO reserves in case they’re needed for maintenance.

- Understocked MROs result in equipment downtime and high supply chain parts

- Overstocked MROs result in overspending for supply chain and additional costs

A good Asset Information Management tool will provide “Where Used” reports, which can be used to correctly set min/max levels for MROs. For more information about this, please visit: https://metanoiacorp.com/video-aic-demo/

Bills of Materials provide insights for Reliability programs

When parts are used during maintenance, they need to be added to a work order within the CMMS. If a company does not have BOMs, they are added from an unstructured Material Master, which is essentially just a long list of parts without any information about components. By selecting a part from a Bill of Material, reliability teams can track which specific component is in need of repair. This provides valuable insights to identify which parts or components are “bad actors” and gear preventive maintenance to reduce further downtime.

BOMs are used to reduce inventory

By aligning every part in the Material Master to a Bill of Material, asset management groups create a list of unused parts. These parts often are unmatched because they’re no longer used or they’re a duplicate/alternate part. In both cases, many of these parts can be retired, saving organizations in warehouse and carrying costs.

Why don’t all asset management groups have BOMs?

BOMs are difficult to build and maintain. Bill of material development programs require a ton of man-power and diligence with continuous improvement.

What are the best BOM creation services?

Metanoia offers the world’s best asset master data services to build BOMs and align them to Material Masters. For more information, please visit: https://metanoiacorp.com/metanoia-services-overview-build-interactive-parts-catalogs-from-static-equipment-diagrams/

What is the best Bill of Materials tool?

Asset Information Center (AIC) is purpose built to manage BOMs and other asset information. Many organizations forego the management of BOMs in their CMMS, and elect to use AIC instead. It’s easier to use, captures all the data necessary, and pairs well with Metanoia’s BOM creation services. For more information, please visit: https://metanoiacorp.com/video-aic-demo/